Frontiers of Chemical Science and Engineering >

Characterization of particle deposition during crossflow filtration as influenced by permeate flux and crossflow velocity using a microfluidic filtration system

Received date: 24 Mar 2020

Accepted date: 21 May 2020

Published date: 15 Jun 2021

Copyright

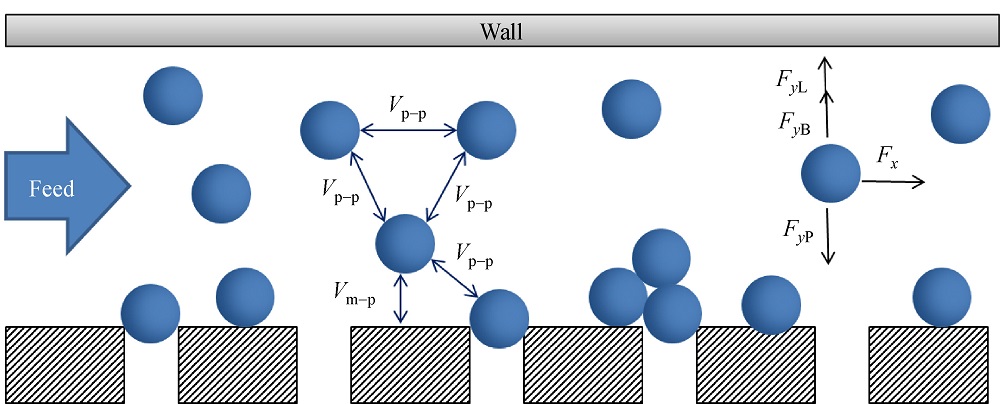

Particle deposition during crossflow filtration is significantly influenced by the operating conditions, in particular the permeate flux and crossflow velocity. However, there is a lack of detailed knowledge about how deposit layer structures and distributions depend on operating parameters. This study uses a microfluidic visualisation filtration system to examine the influence of operating conditions on the deposition process during crossflow ultrafiltration from a microscopic perspective. Increasing the permeate flux caused an increasing amount of deposition and a thicker deposit layer. Higher crossflow velocities reduced the extent of deposition. The degree of deposition varied over a range of operating conditions due to the altered hydrodynamic forces exerted on the particles, which can be examined by the deposition probability according to an existing model. Building on this, an empirical correlation between the deposition probability and volume of deposition as a function of filtration time was developed, which gave good agreement with experimental results. The effect of solution conditions was also involved in this correlation as a interaction energies. This could be useful for predicting the dynamic deposition process during crossflow filtration over a range of operating and solution conditions.

Hongzhan Di , Gregory J. O. Martin , Dave E. Dunstan . Characterization of particle deposition during crossflow filtration as influenced by permeate flux and crossflow velocity using a microfluidic filtration system[J]. Frontiers of Chemical Science and Engineering, 2021 , 15(3) : 552 -561 . DOI: 10.1007/s11705-020-1962-5

| 1 |

Zeman L J, Zydney A. Microfiltration and Ultrafiltration: Principles and Applications. Florida: CRC Press, 2017, 1–618

|

| 2 |

Pabby A K, Rizvi S S, Requena A M S. Handbook of Membrane Separations: Chemical, Pharmaceutical, Food, and Biotechnological Applications. Florida: CRC Press, 2008, 1–812

|

| 3 |

Chen G Q, Leong T S, Kentish S E, Ashokkumar M, Martin G J. Membrane separations in the dairy industry. In: Separation of Functional Molecules in Food by Membrane Technology. Washington: Academic Press, 2019, 267–304

|

| 4 |

Davis R H. Microfiltration in pharmaceutics and biotechnology. In: Current Trends and Future Developments on (Bio-) Membranes. Amsterdam: Elsevier, 2019, 29–67

|

| 5 |

Moslehyani A, Ismail A F, Matsuura T, Rahman M A, Goh P S. Recent progresses of ultrafiltration (UF) membranes and processes in water treatment. In: Membrane Separation Principles and Applications. Amsterdam: Elsevier, 2019, 85–110

|

| 6 |

Field R. Fundamentals of fouling. Membranes for Water Treatment, 2010, 4: 1–23

|

| 7 |

Guo W, Ngo H H, Li J. A mini-review on membrane fouling. Bioresource Technology, 2012, 122: 27–34

|

| 8 |

Tang C Y, Chong T H, Fane A G. Colloidal interactions and fouling of NF and RO membranes: a review. Advances in Colloid and Interface Science, 2011, 164(1-2): 126–143

|

| 9 |

Wang X, Zhou M, Meng X, Wang L, Huang D. Effect of protein on PVDF ultrafiltration membrane fouling behavior under different pH conditions: interface adhesion force and XDLVO theory analysis. Frontiers of Environmental Science & Engineering, 2016, 10(4): 12

|

| 10 |

Lee J, Jeong S, Ye Y, Chen V, Vigneswaran S, Leiknes T, Liu Z. Protein fouling in carbon nanotubes enhanced ultrafiltration membrane: fouling mechanism as a function of pH and ionic strength. Separation and Purification Technology, 2017, 176: 323–334

|

| 11 |

Di H, Martin G J, Sun Q, Xie D, Dunstan D E. Detailed, real-time characterization of particle deposition during crossflow filtration as influenced by solution properties. Journal of Membrane Science, 2018, 555: 115–124

|

| 12 |

van der Marel P, Zwijnenburg A, Kemperman A, Wessling M, Temmink H, van der Meer W. Influence of membrane properties on fouling in submerged membrane bioreactors. Journal of Membrane Science, 2010, 348(1-2): 66–74

|

| 13 |

Zhu X, Loo H E, Bai R. A novel membrane showing both hydrophilic and oleophobic surface properties and its non-fouling performances for potential water treatment applications. Journal of Membrane Science, 2013, 436: 47–56

|

| 14 |

Simon A, Price W E, Nghiem L D. Changes in surface properties and separation efficiency of a nanofiltration membrane after repeated fouling and chemical cleaning cycles. Separation and Purification Technology, 2013, 113: 42–50

|

| 15 |

Wang X, Chen G Q, Zhang W, Deng H. Surface-modified anion exchange membranes with self-cleaning ability and enhanced antifouling properties. Journal of the Taiwan Institute of Chemical Engineers, 2019, 105: 8–16

|

| 16 |

He Z, Miller D J, Kasemset S, Paul D R, Freeman B D. The effect of permeate flux on membrane fouling during microfiltration of oily water. Journal of Membrane Science, 2017, 525: 25–34

|

| 17 |

She Q, Tang C Y, Wang Y N, Zhang Z. The role of hydrodynamic conditions and solution chemistry on protein fouling during ultrafiltration. Desalination, 2009, 249(3): 1079–1087

|

| 18 |

Wang Y N, Tang C Y. Protein fouling of nanofiltration, reverse osmosis, and ultrafiltration membranes—the role of hydrodynamic conditions, solution chemistry, and membrane properties. Journal of Membrane Science, 2011, 376(1-2): 275–282

|

| 19 |

Mattsson T, Lewis W J, Chew Y J, Bird M R. The use of fluid dynamic gauging in investigating the thickness and cohesive strength of cake fouling layers formed during cross-flow microfiltration. Separation and Purification Technology, 2018, 198: 25–30

|

| 20 |

Ngene I S, Lammertink R G, Wessling M, van der Meer W. A microfluidic membrane chip for in situ fouling characterization. Journal of Membrane Science, 2010, 346(1): 202–207

|

| 21 |

Ding A, Liang H, Li G, Derlon N, Szivak I, Morgenroth E, Pronk W. Impact of aeration shear stress on permeate flux and fouling layer properties in a low pressure membrane bioreactor for the treatment of grey water. Journal of Membrane Science, 2016, 510: 382–390

|

| 22 |

Miller D J, Kasemset S, Paul D R, Freeman B D. Comparison of membrane fouling at constant flux and constant transmembrane pressure conditions. Journal of Membrane Science, 2014, 454: 505–515

|

| 23 |

Choi H, Zhang K, Dionysiou D D, Oerther D B, Sorial G A. Influence of cross-flow velocity on membrane performance during filtration of biological suspension. Journal of Membrane Science, 2005, 248(1-2): 189–199

|

| 24 |

Lian B, Wang Y, Le-Clech P, Chen V, Leslie G. A numerical approach to module design for crossflow vacuum membrane distillation systems. Journal of Membrane Science, 2016, 510: 489–496

|

| 25 |

Bowen W R, Jenner F. Theoretical descriptions of membrane filtration of colloids and fine particles: an assessment and review. Advances in Colloid and Interface Science, 1995, 56: 141–200

|

| 26 |

Stamatakis K, Tien C. A simple model of cross-flow filtration based on particle adhesion. AIChE Journal. American Institute of Chemical Engineers, 1993, 39(8): 1292–1302

|

| 27 |

Di H, Martin G J, Dunstan D E. A microfluidic system for studying particle deposition during ultrafiltration. Journal of Membrane Science, 2017, 532: 68–75

|

| 28 |

Bowen W R, Yousef H N, Calvo J I. Dynamic crossflow ultrafiltration of colloids: a deposition probability cake filtration approach. Separation and Purification Technology, 2001, 24(1-2): 297–308

|

| 29 |

O’neill M E. A sphere in contact with a plane wall in a slow linear shear flow. Chemical Engineering Science, 1968, 23(11): 1293–1298

|

| 30 |

Altmann J, Ripperger S. Particle deposition and layer formation at the crossflow microfiltration. Journal of Membrane Science, 1997, 124(1): 119–128

|

/

| 〈 |

|

〉 |