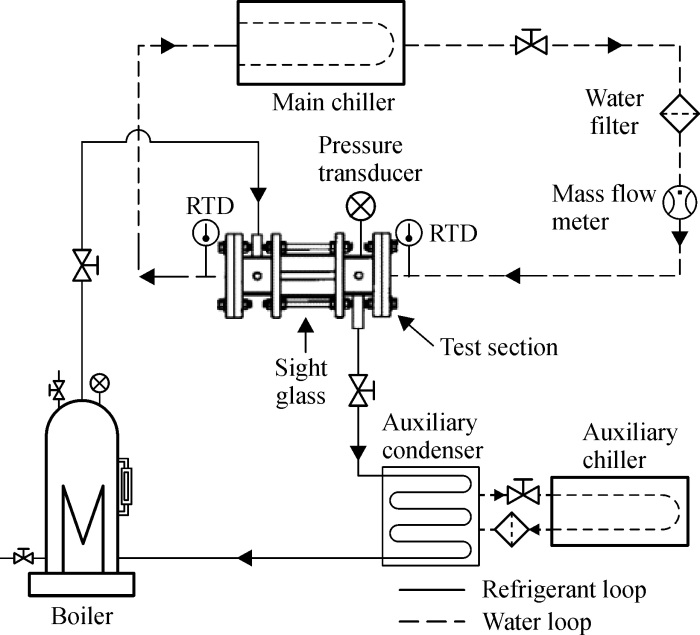

The freons or hydrocarbons mentioned above are either eliminated refrigerants or alternative refrigerants that are more environmentally friendly in the refrigeration and air-conditioning field. Therefore, as presented in Table 4, the saturation temperatures were mostly between 30°C and 45°C in the experiments. As shown in Fig. 7, an experimental platform was built by Jung et al. [

27,

57,

58], in which the vapor condensed through a counter-current heat exchanger with the cooling water inside the tube. In addition, the other experimental devices to be discussed below were similar to this apparatus. The condensation heat transfer processes of 11 refrigerants including propane outside the plain tubes and 5 refrigerants outside the low-fin tubes and Turbo-C tubes were investigated in this experiment. The relationship between the condensation HTCs of 8 refrigerants and wall subcooling was plotted in Fig. 8. All refrigerants showed that the condensation HTC decreased with the increase of wall subcooling, while R32 had the highest HTC among the tested refrigerants. Finally, the heat transfer correlation of Nusselt’s theoretical solution [

25] was revised, and a new correlation for condensation heat transfer outside the tube was obtained based on the experimental data, of which the fitting deviation was within 3%, as tabulated in Table 2. Park and Jung [

59] experimentally studied the condensation heat transfer of 6 flammable refrigerants, including propane, outside the low-fin tubes and Turbo-C tubes. It was found that the HTCs calculated by the correlation developed by Beatty and Katz [

71], which predicted the condensation HTC outside the low-fin tubes, were lower than the present data due to the lack of consideration of surface tension. It was evident that Turbo-C tubes had a better condensation heat transfer performance compared with the low-fin tubes. Gebauer et al. [

60] conducted a similar experiment for the condensation of propane and R134a outside the smooth tubes, standard finned tubes, and high-performance tubes, of which water was the cold and heat source. It was worth mentioning that both single tubes and tube bundles were studied in the heat transfer performance. Then, the experimental data were compared with the results of theoretical calculation models and CFD simulations. Derived from the additional structure that was not conducive to the drainage of condensates, the high-performance tube showed a greater bundle effect compared with the standard finned tubes, though it performed better in heat transfer. At the same time, it was also found that the effect of the coating in increasing the thermal resistance was greater than that in reducing the surface free energy. As a result, the HTC was reduced while the bundle effect could not be reduced by coating. Sajjan et al. [

61,

62] conducted a visual experimental investigation of the condensation heat transfer characteristics outside the horizontal smooth tube for R600a at different pressures and wall subcooling temperatures. It was found that the HTC could be improved by increasing the saturation pressure or reducing the wall subcooling temperature. The HTC predicted by Nusselt’s theoretical solution was lower at a high pressure and higher at a low pressure than the experimental data. Meanwhile, a similar experimental study was conducted on fin tubes with different fin densities. Then, the fin density with the highest HTC was obtained, and the functional relationship between heat flux and wall subcooling temperature was obtained for different fin densities. Finally, a comparison was made between different theoretical correlations and experimental data, and the explanations for the deviations were given. Ji et al. [

63] performed an experiment to investigate the condensation heat transfer characteristics of three refrigerants, including propane, outside the smooth tubes, and the enhanced titanium tubes. The effects of heat flux, refrigerant, and saturation temperature on the HTC were discussed. It was shown that the condensation HTCs at the saturation temperature of 35°C were similar to that at 40°C for R134a and R1234ze(E). However, it was worth mentioning that, for propane, the HTCs of condensation on the enhanced tube increased with the increase of saturation temperature, while the opposite was true on the smooth tube. The experimental data and the results calculated by five heat transfer correlations, which predicted condensation outside the enhanced tubes, were also compared in this study. The calculated values of the correlations had large deviations from the experimental data, of which the smallest was between –42.3% and –14.8%. Chen et al. [

64] conducted boiling and condensation heat transfer experiments for propane in two sleeve-type smooth circular tubes, where nitrogen and water were used as cold and heat sources, respectively. In addition to common factors such as the inlet temperature and the flowrate of water, the effect of the inclination of the tube on the heat transfer of propane was investigated. Finally, the deviations between the existing boiling and condensation correlations and the experimental data were plotted. Moreover, several studies on mixed working fluids were conducted. For example, Pang and Mi et al. [

65,

66] experimentally studied the heat transfer characteristics of propane and the mixture of propane and ethane in the shell side of spiral baffle heat exchangers. Two new heat transfer correlations were developed, and the effects of dryness, heat flux, and mass flux on the HTCs in the shell side were also studied. The condensation heat transfer performance of R134a outside a single fin tube and fin tube bundle was studied by Al-Badri et al. [

67], then the effects of fin structure and fin density were explored. In the experiment of tube bundle, as the fin density increased, the formation of sheet mode condensation was delayed, and the HTC was increased. It was worth mentioning that the effects of different tube types on the heat transfer of single tube and tube bundle were different. For the condensation on single-tubes, the HTCs on enhanced finned tubes (EFT) were significantly higher than those on standard finned tubes (SFT). However, the additional structure of EFT promoted the formation of sheet mode condensation in tube bundle, and the tube bundle effect was more pronounced, which was similar to the results of Gebauer et al. [

60]. Therefore, as the number of tube rows increased, the condensation HTC of SFT decreased less than that of EFT. An experimental study on the condensation of R410A outside the smooth tube and two newly developed enhanced tubes was conducted by Li et al. [

68]. The effects of saturation temperature, mass flux, and steam quality were discussed, and a new heat transfer correlation was developed based on Nusselt’s theoretical solution. Ko and Jeon [

69] conducted an experimental study on film condensation of three new green and environmentally friendly alternative refrigerants outside the smooth tube and three enhanced tubes. The corresponding values of the parameters in the functional relationships between heat flux and HTC were obtained for different combinations of enhancement tubes and refrigerants. Besides, the effect of the width of the annulus on the condensation outside the enhanced tube in the tube-in-tube heat exchanger was experimentally studied by Tang et al. [

70], with R134a as the working fluid.